The 'product life cycle' generally refers to the stages from idea to disposal of a product. As you can see in Table 1.4, it comprises six phases.

|

In the first stage, product planning, customer needs, business trends, and market competition are analysed, and a team is formed to plan the product requirements, and to set timelines for its upcoming design, development, validation and production. |

|

The design and development phase comprises the preparation of detailed product specifications to meet the requirements already set. The concept design is then worked out, including necessary subsystems. This is followed by a detailed design for the product, and the selection of materials and components. Note that this is an essentially iterative task. |

|

Two major steps occur in verification and validation phase. First, a small number of product prototypes are built for design verification testing. If all criteria are met, pilot production may be initiated. If not, then the product must be redesigned. The second step is product validation testing, aimed at validating the production process itself. That is, it must be shown that the quality of the product wont be degraded when the production process runs at full capacity. |

|

If the product’s design and production process have been validated, then full-scale production can begin. Note there may still be the need for testing end products at this stage before they are sent to customers. |

|

As the name suggests, the field deployment stage is characterized by the product going out ‘into the field’ as customers use it. This phase involves marketing, and sales and technical support. The product’s actual field performance may also need to be monitored, and improvements can still be made at this stage |

|

Disposal occurs at the end of a product’s life cycle, I.e. when, for whatever reason, it’s no longer worth using or repairing. In some cases, the manufacturer may still need to provide support at this stage in terms of disposing of, dismantling, or recycling the products. |

The breakdown of the product life cycle into six phases is actually a traditional and limited view that was originally developed for manufacturers. But as product environmental, health and safety (EHS) issues are becoming increasingly important and in the public interest, the structure of the product life cycle has evolved into variants that provide more comprehensive coverage of other elements and parties, such as consumers, government, and recyclers. You'll see an example in Activity 7.

As you can see, recent product life cycle models are more comprehensive. Many have been and are being developed in the context of Design for Environment (DfE). Note that DfE actually encompasses three areas:

- design for environmental processing and manufacturing

- design for environmental packaging

- design for disposal, reuse or recycling.

The next reading explains this, along with industrial ecology, which emphasizes the product's interaction with the ecosystem at each phase of its life cycle. It also introduces the product-system concept — considering the product and its life cycle as a whole system that encompasses its environmental, social and technological context.

Reading

Read the first part of the article at the following website. Stop at the heading 'Life cycle approach to design: Methods and techniques'.

Giudice, F (2006) 'Life cycle concept' in 'Product design for the environment: Concepts'.

In summary, the complete product life cycle comprises:

- need recognition;

- design and development;

- resource extraction/sourcing;

- material processing;

- production/manufacturing;

- packaging and transportation;

- use/utilization; and

- reuse/recycle/disposal.

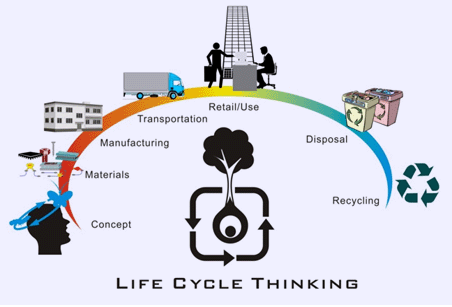

Figure 1.1 gives an overall picture.

Source: http://www.dlinkgreen.com/greensupplychainmanagement.asp

By now it should be evident to you that a complete life cycle approach is advantageous. Life cycle thinking facilitates the making of environmentally-responsible products that span 'cradle-to-cradle' lives as opposed to 'cradle-to-grave' lives. This approach is also applicable in developing products with consideration for human health impacts and user safety. The idea is to integrate as many relevant measures as possible at each phase.

- 16770 reads