Available under Creative Commons-ShareAlike 4.0 International License.

Modernization involves a lot of things happening at once at the company's thirty plants around the globe. Old fashioned assembly lines and their large inventories of parts are being replaced with highly automated clusters or cells that produce components for final assembly. The company is "out sourcing" a lot of noncritical parts, such as sheet-metal stampings, to suppliers, finding that it can save a lot of money by shopping the world carefully for the lowest-cost providers. The main objective is to sharply cut inventory costs. This has to be done through advanced logistics, getting delivery of needed parts to the manufacturing cell "just-in-time, n to quote the modern jargon. To make the entire world-wide process flow, a computerized network, using software still being improved, controls what is happening in company and supplier plants. 1

George Melloan

LEARNING OBJECTIVES

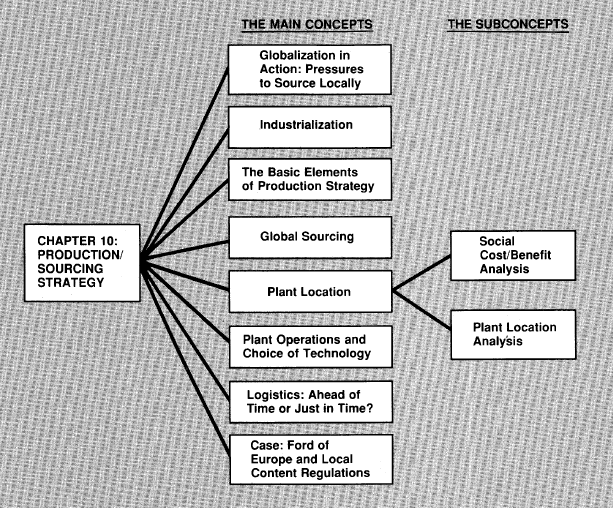

After studying the material in this chapter, the student should be familiar with the following concepts:

- Production/sourcing in international business

- The main components of a production/sourcing strategy

- Industrialization and the three industrial revolutions

- Lessons from industrialization experiences

- Types of global sourcing

- International subcontracting

- Social cost/benefit analysis in locating plants

- International logistics

- Just-in-time materials handling

- Local content regulations

- 4194 reads