The most accurate and time-consuming estimating method is to identify the cost of each item in each activity of the schedule, including labor and materials. If you view the project schedule as a hierarchy where the general descriptions of tasks are at the top and the lower levels become more detailed, finding the price of each item at the lowest level and then summing them to determine the cost of higher levels is called bottom-up estimating.

Example: Bottom-Up Estimate for John’s Move

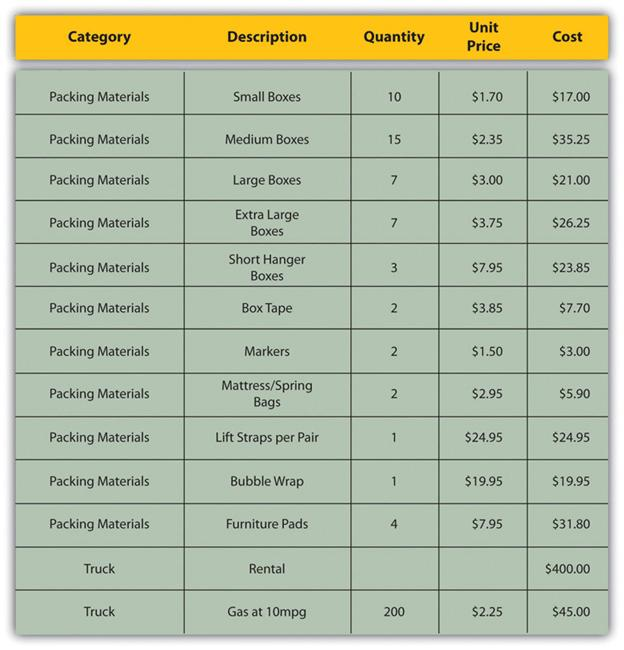

After evaluating the bids by the moving companies, John decides the savings are worth his time if he can get the packing done with the help of his friends. He decides to prepare a detailed estimate of costs (Figure 12.3 Detailed Cost Estimate ) for packing materials and use of a rental truck. He looks up the prices for packing materials and truck rental costs on company websites and prepares a detailed list of items, quantities, and costs.

This type of estimate is typically more accurate than an analogous or parametric estimate. In this example, the sum of packing materials and truck expenses is estimated to be $661.25.

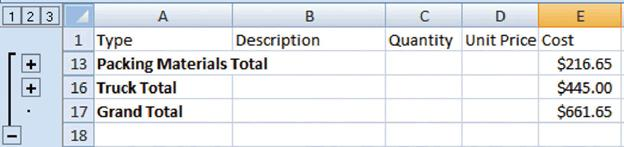

The estimate can be rolled up—subtotaled—to display less detail. This process is made easier using computer software. On projects with low complexity, the cost estimates can be done on spreadsheet software. On larger projects, software that manages schedules can also manage costs and display them by activity and category. For example, the subtotal feature could be used in Excel and collapsed to show the subtotals for the two categories of costs (Figure 12.2 Sum of Detailed Costs by Type ).

- 7658 reads