Some companies, including Walmart, are beginning to experiment with new technologies such as electronic product codes in an effort to better manage their inventories. An electronic product code (EPC) is similar to a barcode, only better, because the number on it is truly unique. You have probably watched a checkout person scan a barcode off of a product identical to the one you wanted to buy—perhaps a pack of gum—because the barcode on your product was missing or wouldn’t scan. Electronic product codes make it possible to distinguish between two identical packs of gum. The codes contain information about when the packs of gum were manufactured, where they were shipped from, and where they were going to. Being able to tell the difference between “seemingly” identical products can help companies monitor their expiration dates if they are recalled for quality of safety reasons. EPC technology can also be used to combat “fake” products, or knockoffs, in the marketplace.

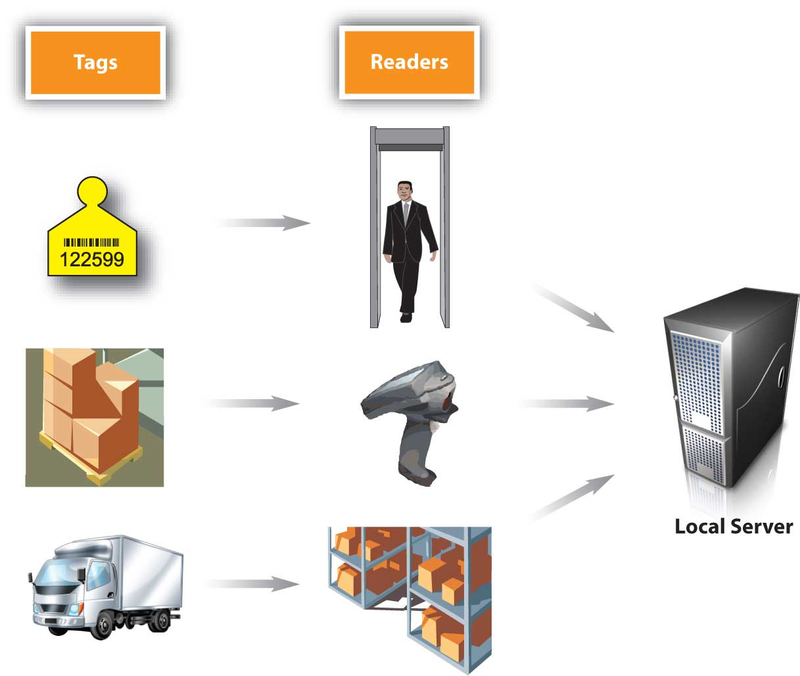

Electronic product codes are stored on radio-frequency identification (RFID) tags. A radio-frequency identification (RFID) tag emits radio signals that can record and track a shipment as it comes in and out of a facility. If you have unlocked your car door remotely, microchipped your dog, or waved a tollway tag at a checkpoint, you have used RFID technology. 1Because each RFID tag can cost anywhere from $0.50 to $50 each, they are generally used to track larger shipments, such cases and pallets of goods rather than individual items. See Figure 9.4 How RFID Tagging Works to get an idea of how RFID tags work.

Some consumer groups worry that RFID tags and electronic product codes could be used to track their consumption patterns or for the wrong purposes. But keep in mind that like your car-door remote, the codes and tags are designed to work only within short ranges. (You know that if you try to unlock your car from a mile away using such a device, it won’t work.)

Proponents of electronic product codes and RFID tags believe they can save both consumers and companies time and money. These people believe consumers benefit because the information embedded in the codes and tags help prevent stockouts and out-of-date products from remaining on store shelves. In addition, the technology doesn’t require cashiers to scan barcodes item by item. Instead an electronic product reader can automatically tally up the entire contents of a shopping cart—much like a wireless network can detect your computer within seconds. As a customer, wouldn’t that add value to your shopping experience?

KEY TAKEAWAY

The best marketing decisions and supplier selections aren’t enough if your company’s demand forecasts are wrong. Demand forecasting is the process of estimating how much of a good or service a customer will buy from you. If you’re a producer of a product, this will affect not only the amount of goods and services you have to produce but also the materials you must purchase to make them. Demand forecasting is part of a company’s overall inventory control activities. Inventory control is the process of ensuring your firm has an adequate amount of products and a wide enough assortment of them meet your customers’ needs. One of the goals of inventory control is to avoid stockouts without keeping too much of a product on hand. Some companies are beginning to experiment with new technologies such as electronic product codes and RFID tags in an effort to better manage their inventories and meet their customers’ needs.

REVIEW QUESTIONS

- Why are demand forecasts made more frequently than sourcing decisions?

- How can just-in-time and vendor-managed inventories add value to products for customers?

- Why and how do companies track products?

- 3557 reads