The record-keeping aspect of OSHA is perhaps as important as following the laws. Companies having fewer than ten employees in some industries are not required to keep records. The purpose of the record keeping does not imply that the employee or the company is at fault for a illness or injury. In addition, just because a record is kept doesn’t mean the employee will be eligible for workersworker’s compensation#8217; compensation. The record-keeping aspect normally refers to the keeping of incidence rates, or the number of illnesses or injuries per one hundred full-time employees per year, as calculated by the following formula

incidence rate=number of injuries and illness ×

200,000 total hours worked by all employees in the period

Two hundred thousand is the standard figure used, as it represents one hundred full-time employees who work forty hours per week for fifty weeks per year. An HR professional can then use this data and compare it to other companies in the same industry to see how its business is meeting safety standards compared with other businesses. This calculation provides comparable information, no matter the size of the company. If the incidence rate is higher than the average, the HR professional might consider developing training surrounding safety in the workplace.

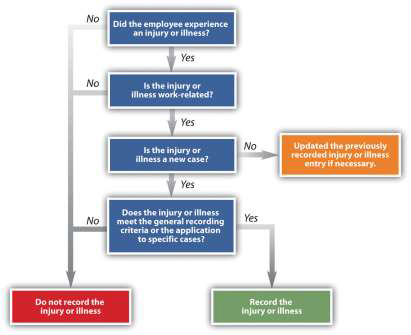

Knowing what should be reported and what shouldn’t be reported is an important component to OSHA. Figure 13.1 provides a decision tree that explains this. Data are reported using a form called OSHA 300, which is shown in .Figure 13.2.As mentioned earlier, OSHA is responsible for enforcing standards. Besides requiring reporting, OSHA also performs inspections. OSHA is responsible for 7 million worksites across the country and so, of course, has to prioritize which ones it visits. OSHA has five main priorities for inspecting sites. First, it will inspect imminent danger situations. These are serious dangers that could cause death or serious harm. The second priority is for those sites where three or more employees were harmed, suffered illness, or were killed. These events are classified as fatalities or catastrophes and must be reported within an eight-hour time frame. The next priority is responding to complaints, which employees are allowed to file anonymously. Organizations that have had previous violations are prioritized next, and finally, planned programs. A planned program might be an organization that has had safety problems in the past and is working with OSHA to remedy the problem.

Most site visits are unannounced and begin with the inspector introducing himself or herself. Prior to this, the inspector has performed research on the organization to be inspected. Once this occurs, a representative of the organization is assigned to accompany the inspector and the inspector discusses the reasons for the site visit. The HR professional is normally responsible for this task.

The inspector then walks around, pointing out any obvious violations, and then the inspector and representative discuss the findings. Within six months a complete report is sent, along with any citations or fines based on what the inspector found. If the organization is in disagreement with the violation or citation, a follow-up meeting with the OSHA director is scheduled and some fines may be reduced if the organization can show how it has improved and met the standards since the original visit.

OSHA has several penalties (per violation) it can assess on organizations, ranging from $7,000 to $70,000. The higher penalties often are a result of very serious offenses, in which an employee could have been killed, but also are imposed for willful offenses that the employer was aware could cause serious injury or death and did nothing about them. This is considered blatant indifference to the law. For example, Northeastern Wisconsin Wood Products was issued $378,620 in fines for willful violations in the summer of 2011. The violations stemmed from repeat visits and citations to the facility, where no safety changes had been made. Some of the willful violations included lack of guards on dangerous machine belts and band saw blades and open-sided floors without a guardrail to prevent falls. Michael Connors, OSHA’s regional administrator in Chicago, said, “Northeastern Wisconsin Wood Products has a history of failing to comply with OSHA standards. The company has yet to abate many violations cited in previous inspections and are unduly placing their workers at risk.” 1 While any violation of OSHA is serious, a willful violation is more serious, and the fines associated with it represent this.

Fortune 500 Focus

PepsiCo is the world’s largest manufacturer, seller, and distributor of Pepsi-Cola products and generates $119 billion in sales every year. 2 Tropicana juice is owned by Pepsi-Co. In October of 2005, a spark triggered an explosion at a Tropicana juice processing plant in Bradenton, Florida, causing burns to two-thirds of a worker’s body. While the worker survived, he underwent multiple surgeries to treat his burns. In this case, OSHA concluded that the fire could have been prevented if Tropicana had followed basic safety requirements such as risk evaluation, given tools to workers that did not produce sparks, and monitored for a buildup of flammable vapors and ventilated the area. OSHA inspectors tallied up a dozen violations, including two serious ones. Vice president of operations Mike Haycock said the plant has an incidence rate that is far lower than others in the industry, and plants around the country have immediately addressed many of the problems and are constantly working to correct other problems. 3

The irony is that although the Tropicana factory paid $164,250 in fines to OSHA, the company was part of the VPP or Voluntary Protection Program, whose membership benefits include exemption from regular inspections. Even after the fire, in 2007, OSHA formally reapproved the plant as a “star site,” the highest level in VPP, meaning the plant pledged to exceed OSHA standards. 4 OSHA contends the VPP program isn’t perfect but is still a useful model to all employers of what can be achieved. For admission into the VPP program, workplaces must show they have fewer accidents and missed work days than average for their industry. According to Robert Tuttle, president of the local Teamsters union representing Tropicana workers, accidents are more common when employees are shifted out of their normal responsibilities, which is more common as the weak economy has led to staff cuts. 5Tropicana plants have had more than eighty deaths since 2000, varying from preventable explosions to chemical releases to crane accidents. 6 PepsiCo and Tropicana have taken a hard stance on these types of accidents, as each of the plants now has a safety manager trained on OSHA standards to prevent accidents. In addition, strict operating procedures have been implemented to prevent future problems.

Key Takeaways

- Every year, 4,340 fatalities and 3.3 million injuries occur in the workplace in the United States.

- The Occupational Safety and Health Act was passed in 1970, with the goal of providing a safe and healthy work environment for all US workers.

- The Occupational Safety and Health Administration is part of the US Department of Labor and was created as a result of the act in 1970.

- OSHA applies to some specific industries, such as construction, shipyards, and marine terminals. However, some of the OSHA regulations apply to all industries.

- Some states may also have safety requirements that may be more stringent than federal laws.

- Right-to-know laws refer to a material data safety sheet, which discusses the types of chemicals, proper handling and storage, and first aid in case of an accident. These data sheets should be made available to the general public and employees.

- Right-to-know laws also require specific reporting to local and state agencies on chemicals used in certain quantities for some industries.

- OSHA requires recording keeping for all workplace accidents or illness. Record keeping is usually the responsibility of HR, and reports are made via OSHA Form 300.

- OSHA can inspect any site without prior notification. Usually, OSHA will gather information, visit the site, and ask for a representative. The representative is normally the HR person. The site visit will be performed, followed by discussion with the company representative. Within six months of the visit, a report and any penalties will be communicated.

EXERCISES

- Research the Internet for recent OSHA violations and write two paragraphs describing one.

- Research possible strategies to reduce OSHA violations and write a paragraph on at least two methods.

- 3873 reads