In this first part (PLAN) were analyzed the losses in the assembly process area so as to organize the activities to reduce the losses identified in the second part of the analysis (DO). Object of the study was the Mechanical Subgroups ETU - Elementary Technology Unit (in a part of the Cassino Plant Assembly Shop). The aim of this analysis was to identify a program allowing to generate savings policies based on Cost Deployment:

- Identify relationships between cost factors, processes generating costs and various types of waste and losses;

- Find relationships between waste and losses and their reductions.

In fact, in general a production system is characterized by several waste and losses (MUDA), such as:

- Non-value-added activities;

- Low balancing levels;

- Handling losses;

- Delay in material procurement;

- Defects;

- Troubleshooting Machines;

- Setup;

- Breakdown.

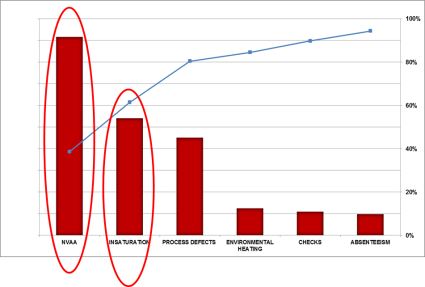

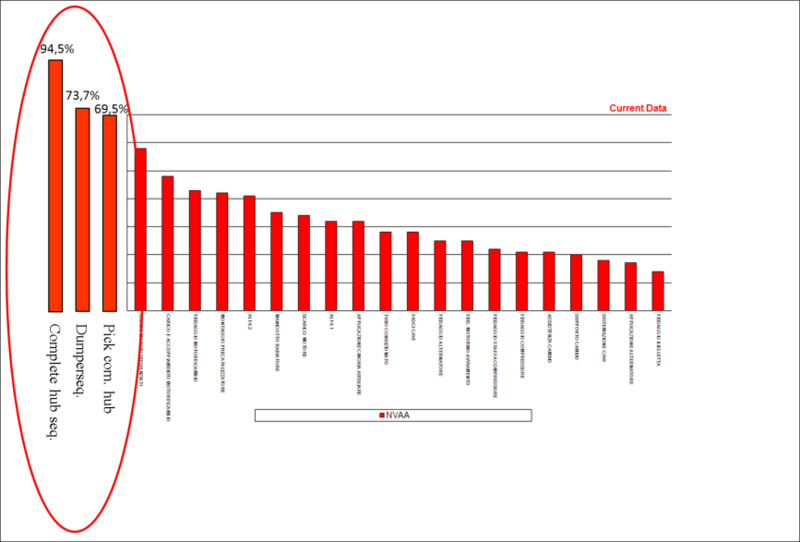

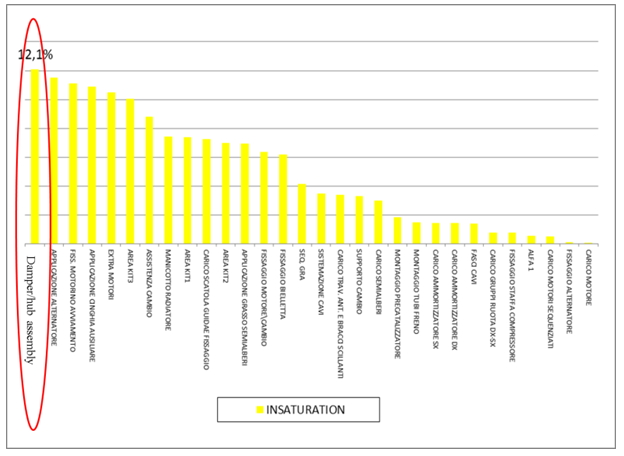

It is important to give a measure of all the losses identified in process examination. The data collection is therefore the “key element” for the development of activities of Cost Deployment. Here below in Figure 1.7 an example of losses identified from CD from the Assembly Shop is shown and in Figure 1.8 is shown an example of CD data collection regarding NVAA (Non-Value-Added Activities) for WO (for this case study we excluded check and rework losses) in the Mechanical Subgroups area. Finally Figure 1.9 shows Analysis of losses Cost Deployment.

- 4969 reads