In recent years, packaging design has developed into a complete and mature communication discipline1. Clients now realize that packages can be a central and critical element in the development of an effective brand identity. The packaging system fulfils a complex series of functions, of which communication is only one. Ease of processing and handling, as well as transport, storage, protection, convenience, and re-use are all affected by packaging.

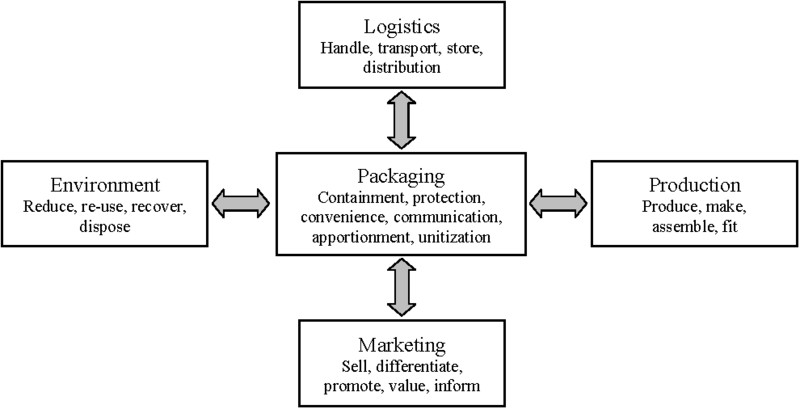

The packaging system has significant implications in OM. In order to obtain successful management of operations, packaging assumes a fundamental role along the whole supply chain and has to be connected with logistics, marketing, production, and environment aspects. For example, logistics requires the packages to be as easy as possible to handle through all processes and for customers. Marketing demands a package that looks nice and is the right size. Packages do not only present the product on the shelf but they also arouse consumers’ expectations and generate a desire to try out the product. Once the product is purchased, packages reassure the consumer of a product’s quality and reinforce confidence2. Production requires only one size of packaging for all kinds of products in order to minimize time and labour cost. The environmental aspect demands the packaging system to be recyclable and to use the least material possible. Figure 8.5 shows the main interactions of the packaging system.

Scholars dealing with packaging disagree about its main function: some researchers emphasize that packaging is a highly versatile marketing tool3, while others consider it mainly as an integral element of the logistics function4; 5. It is necessary to balance the technological and marketing aspects of packaging, indeed it has a significant impact on the efficiency of both logistics (e.g. manufacturing and distribution costs, time required for completing manufacturing and packing operations, which affect product lead time and due date performance to the customer) and the marketing function (e.g. products’ selling, shelf presentation, etc.).

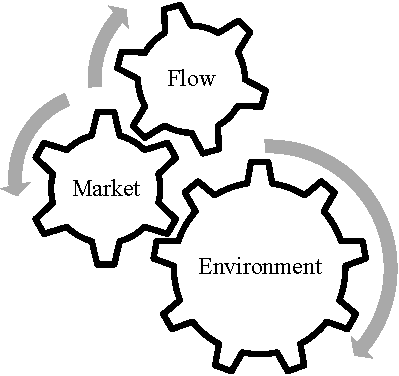

During the recent decades, the environmental aspect is considered by companies that deal with the packaging system. According to Johansson6 the packaging system can be divided in three main functions, that interact each other: flow, market and environment (Figure 8.6).

The flow function consists of packaging features that contribute to more efficient handling in distribution. Packaging logistics, internal material flows, distribution, unpacking, disposal and return handling are included in this function.

Packaging logistics is a relatively new discipline that in recent years has been developed and has gained increasing attention in terms of the strategic role of logistics in delivering competitive advantage by the industrial and scientific community7 ; 8. Industry and science attribute different maturity levels to the subject depending on country and culture. According to Saghir9, the concept of packaging logistics focuses on the synergies achieved by integrating packaging and logistics systems with the potential of increased supply chain efficiency and effectiveness, through the improvement of both packaging and logistics related activities. A more recent definition of packaging logistics is attributed to Chan et al.10, who describe packaging logistics as the interaction and relationship between logistics and packaging systems that improve add-on values on the whole supply chain, from raw material producers to end users, and the disposal of the empty package, by re-use, material recycling, incineration or landfill. Both the definitions (11; 12) focus on the importance of the packaging logistics system, mainly in order to improve the efficiency of the whole supply chain.

In the market function, things like design, layout, communication, ergonomic aspects that create value for the product and the brand are important features for the packaging system13. The purpose of the market function is to satisfy customers and to increase product sales.

During recent decades the link between packaging and marketing is analysed in depth by several authors, and packaging has been studied as a marketing instrument that can influence some specific aspects, such as product positioning, consumer attention, categorization and evaluation, usage behaviour, intention to purchase or brand communication14. The aspect is significant since the package plays the role of an important interface between the brand owner and the consumer. The initial impression of product quality by the consumers is often judged by the impression of the package15.

In the current operational environment, planning innovations must take into account not only marketing and logistics functions, but also a factor that is emerging as increasingly important: the environmental aspect. It aims to reduce the negative effects of the packaging system on the environment. Issues like the use of fewer inputs for the same outputs and the re-use of materials, facilitate the recycling of packaging16. Verruccio et al. 17 suggest that an increasing number of companies are choosing approaches that take care of the environmental aspects. It is further established that the design of the packaging system heavily influences the environmental aspect of activities in the supply chain 18; 19; 20; 21.

With regard to packaging logistics, the use of an appropriate packaging system (in terms of functions, materials, size and shape) can improve the management of operations22:

- Facilitate goods handling. This function considers the following aspects:

- a. Volume efficiency: this is a function of packaging design and product shape. In order to optimize the volume efficiency of a package, this function can be split into two parts, internal and external filling degree. The first regards how well the space within a package is utilized. When using standardized packages with fixed sizes, the internal filling degree might not always be optimal. The external filling degree concerns the fitting of the primary packages with secondary and of secondary with tertiary23. Packages that perfectly fill each other can eliminate unnecessary handling and the risk of damage, but it is important not to be too ambitious. Too much packaging may be too expensive, and there is a point where it is less costly to allow some damage than to pack for zero damage;

- b. Consumption adaptation: the quantity of packages must be adapted to the consumption in order to keep costs low and not to tie unnecessary capital. Moreover it is desirable to have flexible packages and a high turnover of the packaging stock24;

- c. Weight efficiency: the package must have the lowest possible weight, because volume and weight limit the possible amount to transport. The weight is even more important when packages are handled manually25;

- d. Handleability: the packaging must be easy to handle for people and automatic systems working in the supply chain, and final customers26. According to Regattieri et al.27; 28, the handleability is considered the most critical packaging quality attribute by Italian companies and users;

- Identify the product. The need to trace the position of goods during transport to the final destination can be achieved in different ways, for example by installing RFID tags in packages. Thanks to this new technology, it is possible to identify the position of both packages and products in real time. This system leads to a reduction in thefts, increase in security, mapping of the path of products and control of the work in progress;

- Protect the product. The protection of the product is one of the basic functions of packaging for both companies and users29; 30.An unprotected product could cause product waste, which is negative from both the environmental and the economic point of view. Packages must protect products during manufacturing and assembly (within the factory), storage and picking (within the warehouse) and transport (within the vehicle) from surrounding conditions, against loss, theft and manipulation of goods.

- 14727 reads