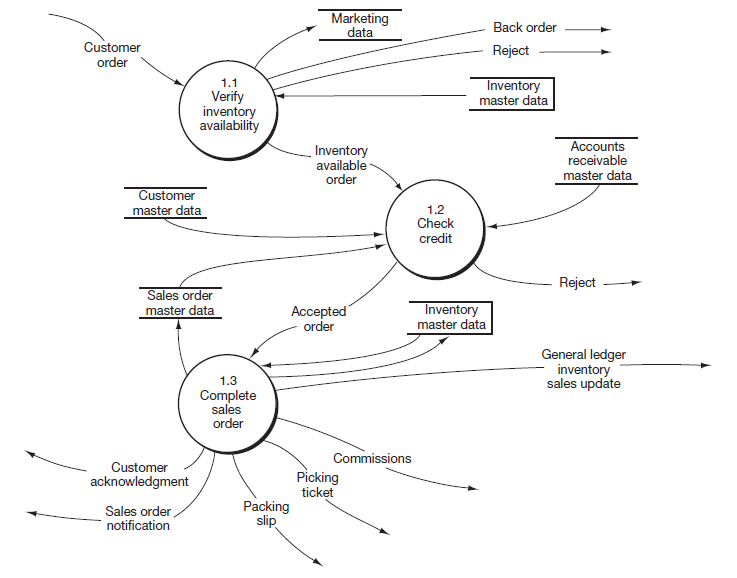

Figure 11.15 provides a lower-level DFD for bubble 1.0 of Figure 11.6, Validate Sales Order.

A customer order is the trigger that initiates process 1.1.1 How does the M/S process validate a customer order? First, process 1.1 verifies the availability of requested inventory by consulting the inventory master data. If there is a sufficient level of inventory on hand to satisfy the request, the order is forwarded for further processing, as depicted by the data flow “Inventory available order.” If a customer orders goods that are not in stock, process 1.1 runs a special back order routine. This routine determines the inventory requirement necessary to satisfy the order and then sends the back order request to the purchasing department. This activity is depicted by the “Back order” data flow, which is a specific type of exception routine (i.e., a specific type of reject stub). Once the goods have been received, the order would then be routinely processed. If the customer refuses to accept a back order, then the sales event terminates, and the order is rejected, as shown by the “Reject” data flow. Information from the order (e.g., in regards to sale region, customer demographics, and order characteristics that reflect buying habits) has potential value to marketing and would be beneficial if recorded with the marketing data.

Next, process 1.2 establishes the customer’s existence and then approves credit. In some cases, another aspect of validating the order could be to ensure that we want to ship the ordered goods to this particular customer. For instance, we may reject an order because we don’t want our goods to be marketed through a discount store outlet.

How does the process complete sales orders? First, process 1.3 receives accepted orders from process 1.2. It then completes the order by adding price information, which is ascertained from the inventory master data. Then, process 1.3 performs the following activities simultaneously:2

- Updates the inventory master data to reflect a reduced quantity on hand

- Notifies the general ledger that inventory has been reduced

- Updates the sales order master data to indicate that a completed sales order has been created

- Notifies the PtoP process of sales commissions that are applicable to salesperson’s payroll account

- Disseminates the sales order.

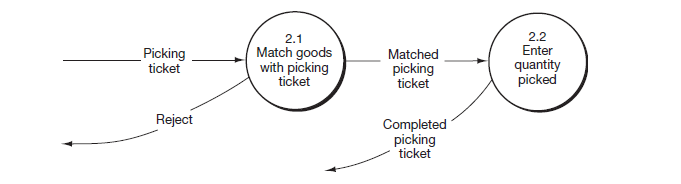

Figure 11.16, a lower-level view of bubble 2.0 of Figure 11.6, describes activities that normally take place in a warehouse. Warehouse personnel receive a picking ticket, locate the goods, take the goods off the shelf (i.e., “pick” the goods), and match the goods with the picking ticket.

The reject stub coming from bubble 2.1 indicates at least two situations that might occur at this point. First, the goods pulled from the shelf might not be those indicated on the picking ticket (i.e., goods have been placed in the wrong warehouse location). Second, sufficient goods may not exist to satisfy the quantity requested. The second situation may arise when goods have been misplaced or when the actual physical balance does not agree with the perpetual inventory balance indicated in the inventory data. These predicaments must be resolved and a back order routine may be initiated to order the missing goods for the customer.

In process 2.2, warehouse personnel write the quantities “picked” on the picking ticket and forward the picking ticket (along with the goods) to the shipping department.

|

Review Question What three exception routines may occur when a customer order is processed? |

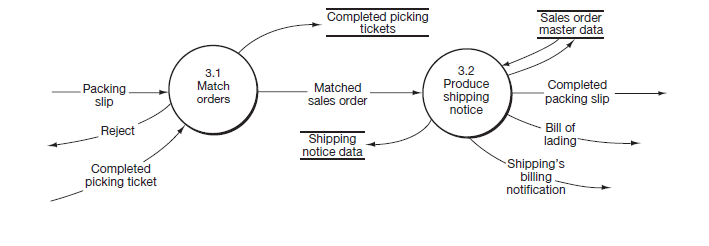

Figure 11.17, a lower-level view of bubble 3.0 in Figure 11.6, describes activities that normally take place in a shipping department. The figure tells us that process 3.1 receives two data flows; namely, the packing slip from process 1.3 of Figure 11.15 and the completed picking ticket from process 2.2 of Figure 11.16. Process 3.1 matches the details of the data flows, looking for consistency between them. If the details agree, the completed picking ticket is filed, and the matched sales order is forwarded to process 3.2. If the details of the data flows do not agree, process 3.1 rejects the order and initiates procedures for resolving any discrepancies.

When process 3.2 receives a matched sales order from process 3.1, it produces and disseminates the shipping notice. The process also updates the shipping notice data and the sales order master data. We generally expect the shipping notice dissemination to include the following data flows: shipping’s billing notification (to notify billing to begin the billing process), bill of lading, and completed packing slip.

|

Review Question How is each lower-level DFD (Figure 11.15, Figure 11.16, and Figure 11.17) “balanced” with the level 0 diagram in Figure 11.6? |

- 4959 reads