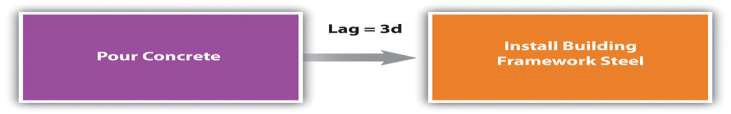

Most activities in a network diagram have a finish-start relationship. If a certain amount of time must go by before a successor activity can begin, the required delay is called lag time. For example, concrete does not reach its full strength for several days after it is poured. Lag time is required between the end of the pouring process and the beginning of construction that puts stress on the concrete as diagrammed in Figure 8.7. Similarly, you must allow lag time for payment checks to be processed by the banking system before you can spend the money.

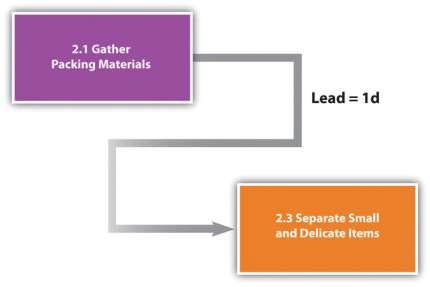

In some cases, the successor activity can overlap the end of its predecessor activity and begin before the predecessor is finished. This is called lead time.

Lead Time in John’s Move

In John’s move, you might begin separating the small and delicate items that will be packed in step 2.3 before you get the packing materials in step 2.1 so that when the materials are available, step 2.3 is already partially completed. If the preparing the small items for packing can overlap its predecessor and shortens the time it takes to accomplish both tasks by a day, it has a lead time of one day.

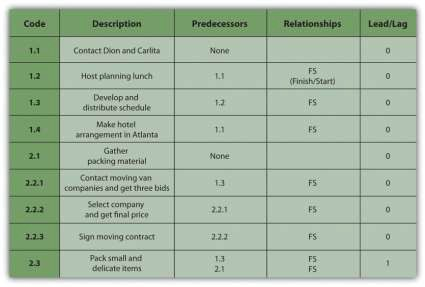

The characteristics and identifiers of an activity are its attributes. At this point in the process of analyzing John’s move, each activity has an identifying code, a short description, predecessors, and lead or lag times, as shown in a partial table of activities in Figure 8.9.

- 2717 reads