|

|

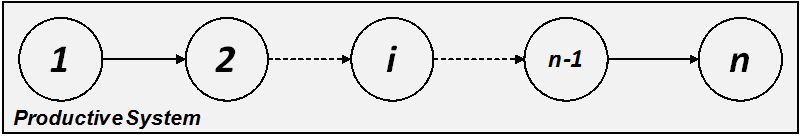

The System OEE measures the systemic performance of a manufacturing system (productive line, floor, factory) which combines activities, relationships between different machines and processes, integrating information, decisions and actions across many independents systems and subsystem1. For its optimization it is necessary to improve coordinately many interdependent activities. This will also increase the focus on the plant-wide picture.

Figure 3.3clarify which is the difference between Equipment OEE and System OEE, showing how the performance of each equipment affects and is affected by the performances of the other connected equipments. These time losses propagation result on a Overall System OEE. Considering the Figure 3.3 we can indeed argue that given a set of i=1,..,n equipments, OEEi of the i th equipment depends on the process in which it has been introduced, due to the availability, performance and quality losses propagation.

According to the model proposed by Huang et al in2, the System OEE (OTE) for a series of nconnected subsystems, is formulated in function of theoretical production rate  relating to the slowest machine (the bottleneck), theoretical

production rate

relating to the slowest machine (the bottleneck), theoretical

production rate  and OEEn of nth station as shown in Table 3.5:

and OEEn of nth station as shown in Table 3.5:

|

|

The OEEn computed in Table 3.5 is the OEE of nth station introduced in the production system (the OEEn when n is in the system and it is influenced by the performance of other n-1 equipments).

According to Table 3.5 the only measure of OEEn is a measure of the performance of the whole system (OTE). This is true because performance data on n are gathered when the station n is already working in the system with the other n-1 station and, therefore, its performance is affected from the performance of the other n-1 prior stations. This means that the model proposed by Huang, could be used only when the system exists and it is running, so OEEn could be directly measured on field.

But during system design, when only technical data of single equipment are known, the same formulation in Table 3.5 can’t be used, since without information on the system OEEn in unknown a-priori. Hence, in this case the Table 3.5 couldn’t provide a correct value of OTE.

- 2097 reads