We run the simulation also for the case study (§ 4). The simulation shown how two stations, with the same theoretical cycle time (200 sec/coil) affected by a triangular distribution with a performance rate of 52% as single machine, have: 48% of performance rate with a capacity buffer of 1 coil and 50% of performance rate with a capacity buffer of 2 coils. But if we consider two stations with the same theoretic cycle time but affects by different triangular distributions so that theoretic performance rates differ, simulation shows how the performance rates of two stations converge towards the lowest one as expected (19), (20).

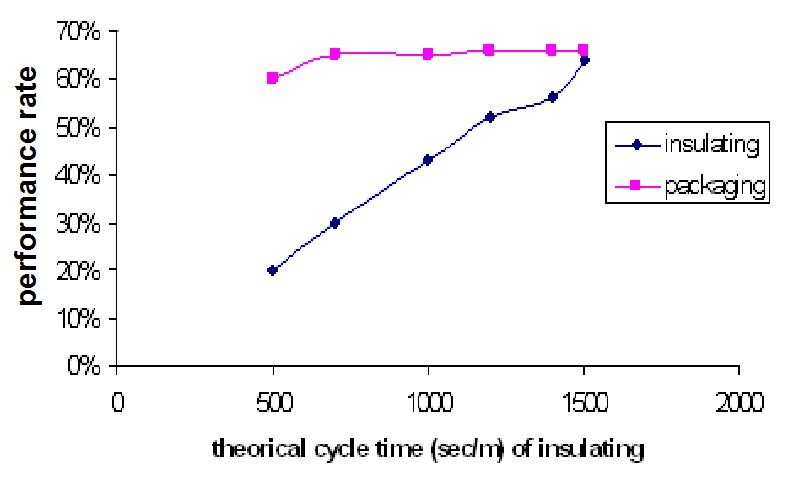

Through the same simulation model we considered also the second type of performance losses propagation, due to the propagation of reduced speed caused by unbalanced line. Figure 3.16 shown the effect of unbalanced cycle time of stations relating to insulating and packaging. The station have the same P as single machine equal to 67% but different theoretical cycle time. In particular insulating, the upstream station, is faster than packaging. Availability and quality rate of stations is set to 1. The buffer capacity is set to 1 coil. A simulation has been run to study the effect of unbalancing station. Theoretical cycle time of insulating has been changed since theoretical cycle time of packaging that is fixed in mean. The simulation points out that insulating has to adapt itself to cycle time of packaging that is the bottleneck station. This results in the model as a lower value for performance rate of insulating station. The same happens often in real systems where the result is influenced by all the efficiency losses at the same time. The effect disappears gradually with a better balancing of two stations as in Figure 3.16 .

- 1954 reads