OM is increasingly connected with the environment and sustainable development (i.e. the development that meets the needs of the present without compromising the ability of future generations to meet their own needs), and it now concerns both the operational drivers of profitability and their relationship with people and the planet.

Following the definition of sustainability by the World Commission on Environment and Development (WCED), Sustainable Operations Management (SOM) is defined as the set of skills and concepts that allow a company to structure and manage its business processes in order to obtain competitive returns on its capital assets without sacrificing the needs of stakeholders and with regard for the impact of its operations on people and environment.

In order to perform sustainable operations, it is necessary to enlarge the perspective of OM, including people and the planet. According to Kleindorfer et al.1, SOM integrates the profit and efficiency orientation of traditional OM with broader considerations of the company’s internal and external stakeholders and its environmental impact. SOM helps companies to become agile, adaptive and aligned, balancing the people and the planet with profits2.

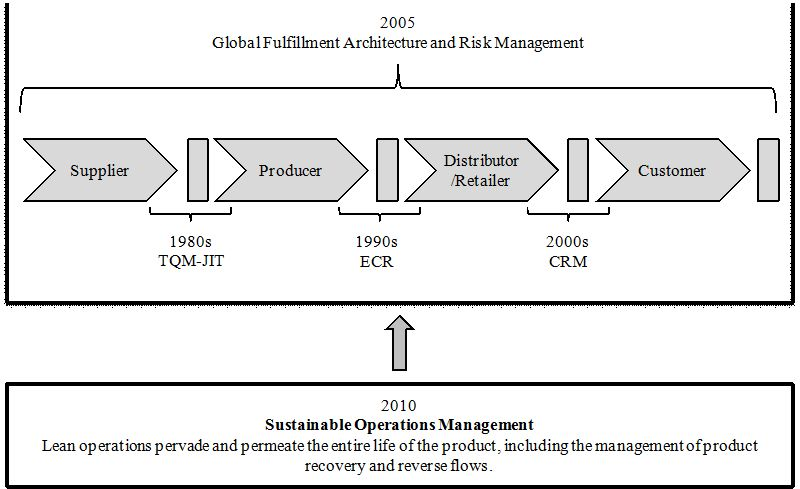

Figure 4.1 has shown the evolution of OM since the 1980s.Figure 8.3 shows the impact of the SOM in the supply chain3. SOM has emerged over recent years and it influences the entire life cycle of the product (e.g. the management of product, recovery and reverse flows).

Considering the sustainability, environmental responsibility and recycling regulations, the packaging system plays an increasingly important role. Several environmental aspects are affected by packaging issues:

- Waste prevention: packages should be used only where needed. Usually, the energy content and material usage of the product being packaged are much greater than that of the package;

- Material minimization: the mass and volume of packages is one of the criteria to minimize during the package design process. The use of “reduced” packaging helps to reduce the environmental impacts;

- Re-use: the re-use of a package or its component for other purposes is encouraged. Returnable packages have long been used for closed loop logistics systems. Some manufacturers re-use the packages of the incoming parts for a product, either as packages for the outgoing product or as part of the product itself;

- Recycling: the emphasis focuses on recycling the largest primary components of a package: steel, aluminium, paper, plastic, etc.;

- Energy recovery: waste-to-energy and refuse-derived fuel in facilities are able to make use of the heat available from the packaging components;

- Disposal: incineration, and placement in a sanitary landfill are needed for some materials.

According to the studies conducted by Regattieri et al.4 ; 5, users and companies have shown an interest in the environment and its link with the packaging system. Indeed, they believe that careful use of packaging can lead to an important reduction in environmental impact. Companies have begun to use recyclable materials (e.g. cardboard, paper, and plastic) and to re-use packages for other activities (for example online retailers are beginning to re-use secondary packages of back products for future shipments). The next section describes the packaging system and its crucial role for the activities along the supply chain, and then in OM.

- 12432 reads