In the early 1990s, the need to improve HRA approaches interested a number of important research and development activities around the world. These efforts led to much progress in first generation methods and the birth of new techniques, identified as second generation. These HRA methods have been immediately unclear and uncertain, substantially because the methods have been defined in terms of what should not be – that is, they should be as the first generation of HRA methods1.While the first generation HRA methods are mostly behavioural approaches, the second generation HRA methods aspire to be of conceptual type2.The separation between generations is evident in the abandonment of the quantitative approach of PRA/PSA in favour of a greater attention to qualitative assessment of human error. The focus shifted to the cognitive aspects of humans, the causes of errors rather than their frequency, the study of the interaction of the factors that increase the probability of error, and the interdependencies of the PSFs3

Second generation HRA methods are based on a cognitive model more appropriate to explain human behaviour. It is evident that any attempt at understanding human performance needs to include the role of human cognition, defined as “the act or process of knowing including both awareness and judgement” by an operator4. From the HRA practitioner’s perspective, the immediate solution to take into consideration human cognition in HRA methods was to introduce a new category of error: “cognitive error”, defined both as failure of an activity that is predominantly of a cognitive nature and as the inferred cause of an activity that fails5. For example, in CREAM, developed by Erik Hollnagel in 1993, maintained division between logical causes and consequences of human error6.The causes of misbehaviour (genotypes) are the reasons that determine the occurrence of certain behaviours, and the effects (phenotypes) are represented by the incorrect forms of cognitive process and inappropriate actions7, 8, 9 .

Moreover, the second generation HRA methods have aimed at the qualitative assessment of the operator’s behaviour and the search for models that describe the interaction with the production process. Cognitive models have been developed, which represent the process logical–rational of the operator and summarise the dependence on personal factors (such as stress, incompetence, etc.) and by the current situation (normal conduction system, abnormal conditions, or even emergency conditions), and models of man–machine interface, which reflect the control system of the production process 10. In this perspective, man must be seen in an integrated system, men–technology–organisation (MTO), or as a team of operators (men) who collaborate to achieve the same objective, intervening in the mechanical process (technology) within a system of organisation and management of the company (organisation) and, together, represent the resources available11, 12 .

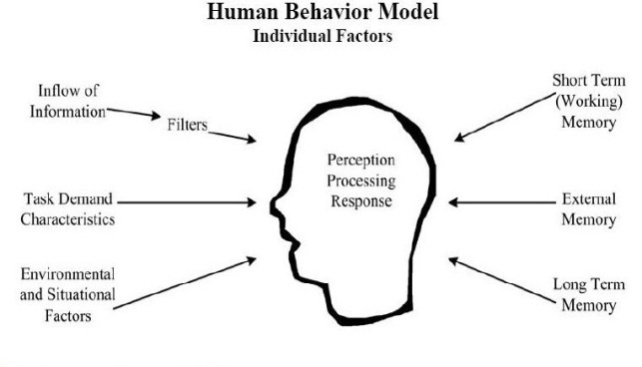

The CREAM operator model is more significant and less simplistic than that of first generation approaches. The cognitive model used is the contextual control model (COCOM), based on the assumption that human behaviour is governed by two basic principles: the cyclical nature of human cognition and the dependence of cognitive processes from context and working environment. The model refers to the IPS paradigm and considers separately the cognitive functions (perception, interpretation, planning and action) and their connection mechanisms and cognitive processes that govern the evolution13 , 14, 15, 16. The standardised plant analysis risk–human reliability analysis method (SPAR-H)17, 18, 19 is built on an explicit information-processing model of human performance, derived from the behavioural sciences literature. An information-processing model is a representation of perception and perceptual elements, memory, sensory storage, working memory, search strategy, long-term memory, and decision-making20 The components of the behavioural model of SPAR-H are presented in Figure 9.3

A further difference between generations relates to the choice and use of PSF. None of the first generation HRA approaches tries to explain how PSFs exert their effect on performance; moreover, PSFs – such as managerial methods and attitudes, organisational factors, cultural differences, and irrational behaviour – are not adequately treated in these methods. PSFs in the first generation were mainly derived by focusing on the environmental impacts on operators, whereas PSFs in the second generation were derived by focusing on the cognitive impacts on operators21. The PSFs of both generations were reviewed and collected in a single taxonomy of performance influencing factors for HRA22

Among the methods of the second generation can be mentioned: a technique for human error analysis (ATHEANA), Cognitive Environmental Simulation (CES), Connectionism Assessment of Human Reliability (CAHR) and Méthode d’Evaluation de la Réalisation des Missions Opérateur pour la Sûreté (MERMOS)23, 24

Many proposed second generation methods still lack sufficient theoretical or experimental bases for their key ingredients. Missing from all is a fully implemented model of the underlying causal mechanisms linking measurable PSFs or other characteristics of the context of operator response. The problem extends to the quantification side, where the majority of the proposed approaches still rely on implicit functions relating PSFs to probabilities25. In short, some of the key shortcomings that motivated the development of new methods still remain unfulfilled. Furthermore, unlike first generation methods, which have been largely validated 26, 27, 28, the second generation has yet to be empirically validated 29.

There are four main sources of deficiencies in current HRA methods30 .

- Lack of empirical data for model development and validation;

- Lack of inclusion of human cognition (i.e. need for better human behaviour modelling);

- Large variability in implementation (the parameters for HRA strongly depend on the methodology used)

- Heavy reliance on expert judgement in selecting PSFs and use of these PSFs to obtain the HEP in human reliability analysis.

- 3529 reads