As the previous paragraphs have underlined, the packaging system has numerous implications along the supply chain (e.g. marketing, production, logistics, purchasing, etc.). In order to define optimal management of the packaging system, it is necessary to evaluate the total packaging cost, made up of e.g. purchasing cost, manufacturing cost, transport and labour cost, management cost, etc. The study conducted by Regattieri et al.1 underlines that most companies do not estimate the total packaging costs and, to confirm this, literature analysis shows the lack of a complete function for calculating the total cost of packaging in a company. For this reason, the authors have developed a complete mathematical model, considering all the cost parameters regarding the packaging system (primary, secondary and tertiary packages and accessories) along the whole supply chain of a manufacturing company.

The model represents added value for companies seeking to estimate the total costs of their packaging system and consequently its impact on total company costs. Moreover, it may be possible to find out the overlooked and oversized packaging factors. The former should be introduced in the calculation of the total packaging costs, while the latter could be reduced or eliminated.

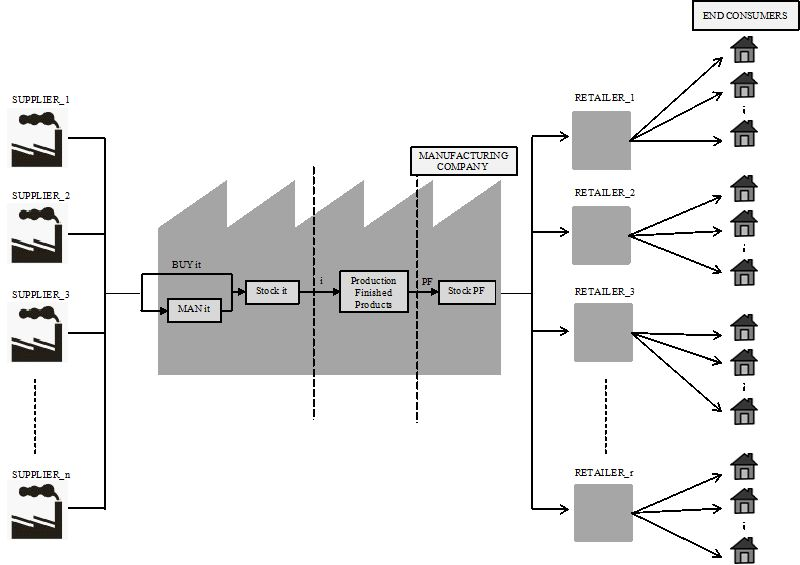

Figure 8.12 shows the simplified supply chain of a manufacturing company.

The manufacturing company can rent or purchase packages (primary, secondary and tertiary and accessories) and raw materials (if the manufacturer produces packages internally) from the supplier n. When goods arrive, they are received in the manufacturer’s receiving area, sorted and stored in the warehouse. If the company has to produce the packaging, the raw materials are picked and brought to the manufacturing area, where packages are made and subsequently stored in the warehouse. The raw materials not used during the manufacturing stage are brought back to the warehouse, creating a reverse flow of materials. When the finished products are produced, the packages are picked from the warehouse and brought to the manufacturing area. The packages not used during the manufacturing stage are brought back to the warehouse, creating a reverse flow of materials. The finished products are packed, put onto a pallet, and delivered to the retailer m. The model considers the possibility to re-use packages after the delivery of the finished products to the final customers and the possible disposal of packages if they are damaged. In addition, the model considers the possibility for the manufacturer to make a profit from sub-products derived from the disposal of packages and/or from the sale of tertiary packages to the final customers.

Table 8.2, Table 8.3 and Table 8.4 describe the indices, variables and cost parameters used in the model.

|

Index |

Domain |

Description |

|

i |

1,…,4 |

Level of package: i=1 (primary package) i=2 (secondary package) i=3 (tertiary package) i=4 (accessories) |

|

t |

1,…,m |

Different packages for each level i |

|

n |

1,…,s |

Suppliers |

|

r |

1,…,q |

Retailers |

|

Variable |

Units |

Description |

Domain |

|---|---|---|---|

|

xnit |

[pieces/year] |

Quantity of raw materials bought by the company from the supplier n to produce package i of type t. |

i=1,…,4; t=1,…,m; n=1,…,s |

|

x’it |

[pieces/year] |

Quantity of package i of type t produced by the manufacturer company from raw materials. |

i=1,…,4; t=1,…,m |

|

ynit |

[pieces/year] |

Quantity of package i of type t bought by the company from supplier n. |

i=1,…,4; t=1,…,m; n=1,…,s |

|

wnit |

[pieces/year] |

Quantity of package i of type t rented by the company from the supplier n. |

i=1,…,4; t=1,…,m; n=1,…,s |

|

rit |

[pieces/year] |

Quantity of disposed package i of type t from which the company has a profit from sub-products. |

i=1,…,4; t=1,…,m |

|

urit |

[pieces/year] |

Quantity of package i of type t sold by the company to the retailer r. |

i=1,…,4; t=1,…,m; r=1,…,q |

|

NORD |

[orders/year] |

Number of orders for buying raw materials and/or packages i of type t. |

|

|

NEXT TRAN nit |

[trips/year] |

Number of trips of raw materials and/or packages i of type t from the supplier n to the manufacturer. |

i=1,…,4; t=1,…,m; n=1,…,s |

|

NINT TRAN it |

[trips/year] |

Number of trips of raw materials and/or packages i of type t from the manufacturer’s receiving area to the warehouse. |

i=1,…,4; t=1,…,m |

|

NINT TRAN1it |

[trips/year] |

Number of trips of raw materials i of type t from the warehouse to the manufacturing area to produce packages from xit. |

i=1,…,4; t=1,…,m |

|

NINT TRAN2it |

[trips/year] |

Number of trips of packages i of type t produced by the manufacturer and transported from the production area to the warehouse. |

i=1,…,4; t=1,…,m |

|

NINT TRAN3it |

[trips/year] |

Number of trips of packages (produced/bought/rented) i of type t from the warehouse to the production area in order to support finished products. |

i=1,…,4; t=1,…,m |

|

NREV INT TRAN2it |

[trips/year] |

Number of trips of packages i of type t not used during the production of finished products and transported from the manufacturing area to the warehouse. |

i=1,…,4; t=1,…,m |

|

NREV INT TRAN1it |

[trips/year] |

Number of trips of the quantity of raw materials i of type t not used during the production of packages and transported from the manufacturing area to the warehouse. |

i=1,…,4; t=1,…,m |

|

NREV EXT TRAN rit |

[trips/year] |

Number of trips of packages i of type t from the retailer r to the manufacturer. |

i=1,…,4; t=1,…,m; r=1,…,q |

|

Parameter |

Nomenclatures |

Units |

Description |

|---|---|---|---|

|

CENG |

Cost of Engineering |

[€/year] |

Cost for studying each type of packaging and for making prototypes. It includes the labour costs of engineering the product. |

|

CORD |

Cost of Purchase Order |

[€/order] |

Cost for managing the internal purchase orders if the manufacturer produces the packaging internally; otherwise it represents the purchase orders for buying and/or renting packaging from suppliers. It includes the labour costs for making the order. |

|

CPUR |

Cost of Purchasing |

[€/piece] |

Purchase cost of raw materials (to produce packaging) and/or packages. |

|

CRENT |

Cost of Rent |

[€/piece] |

Cost to rent packages. |

|

CEXT TRAN |

Cost of External Transport |

[€/travel] |

Cost for transporting raw materials and/or packages from the supplier to the manufacturer: it comprises labour costs, depreciation of vehicles (e.g. truck), cost of the distance travelled. |

|

CREC |

Cost of Receiving |

[€/year] |

Cost for receiving raw materials and/or packages. It includes the labour costs and depreciation of vehicles (e.g. truck, forklift) used to unload products. |

|

CCOND |

Cost of Conditioning |

[€/year] |

Cost for sorting raw materials and/or packages before storing them in the warehouse. It includes the labour costs and depreciation of mechanical devices (if used), for example for unpacking and re-packing products. |

|

CINT TRAN |

Cost of Internal Transport |

[€/travel] |

Cost for transporting raw materials and/or packages from the manufacturer’s receiving area to the warehouse. It includes the labour costs, depreciation of vehicles (e.g. forklift), cost of the distance travelled. |

|

CSTOCK |

Cost of Stocking |

[€/piece] |

Cost for storing raw materials and/or packages in the warehouse. It includes the labour costs and the cost of the space for storing the packages. |

|

CPICK |

Cost of Picking |

[€/piece] |

Cost for picking raw materials from the warehouse for producing the packages. It includes the labour costs and depreciation of vehicles (e.g. forklift) for picking the products. |

|

CINT TRAN1 |

Cost of Internal Transport1 |

[€/travel] |

Cost for transporting raw materials from the warehouse to the manufacturing area to produce the packages. It includes the labour costs, depreciation of vehicles (e.g. forklift), cost of the distance travelled. |

|

CMAN |

Cost of Packages Manufacturing |

[€/piece] |

Cost for producing packages internally; it includes the labour costs, depreciation of production plants and utilities (e.g. electricity, water, gas, etc.). |

|

CREV1 |

Cost of Internal Reverse Logistics1 |

[€/travel] |

Cost of transport for bringing the raw materials not used during manufacturing back to the warehouse. It includes: CREV INT TRAN1: the cost of transport for coming back to the warehouse. It comprises labour costs, depreciation of vehicles used (e.g. forklift), cost of the distance travelled; CREV INT COND1: the cost of conditioning packages to make them re-usable. It comprises the labour costs and depreciation of mechanical devices (if used), for example for unpacking and re-packing products. |

|

CINT TRAN2 |

Cost of Internal Transport2 |

[€/travel] |

Cost for transporting the packages produced by the company from the production area to the warehouse. It includes the labour costs, depreciation of vehicles (e.g. forklift), cost of the distance travelled. |

|

CSTOCK1 |

Cost of Stocking1 |

[€/piece] |

Cost for stocking packages produced internally by the company. It includes the labour costs and cost of the space for storing the packages. |

|

CPICK1 |

Cost of Picking1 |

[€/piece] |

Cost for picking packages (produced/bought/rented) from the warehouse. It includes the labour costs and depreciation of vehicles (e.g. forklift) for picking the packages. |

|

CINT TRAN3 |

Cost of Internal Transport3 |

[€/travel] |

Cost for transporting packages from the warehouse to the manufacturing area. It includes the labour costs, depreciation of vehicles (e.g. forklift), cost of the distance travelled. |

|

CREV2 |

Cost of Internal Reverse Logistics2 |

[€/travel] |

Cost of transport for bringing packages not used during the manufacturing of finished products back to the warehouse. It includes: CREV INT TRAN2: the cost of transport for coming back to the warehouse. It comprises the labour costs, depreciation of vehicles used, cost of the distance travelled; CREV INT COND2: the cost of conditioning packages to make them re-usable. It comprises the labour costs and depreciation of mechanical devices (if used), for example for unpacking and re-packing products. |

|

CRE-USE |

Cost of Re-Use |

[€/year] |

Cost of re-using packaging after the delivery of finished products to the customer. It includes: CREV EXT TRAN: the cost of transport for coming back to the company. It comprises the labour costs, depreciation of vehicles used (e.g. truck), cost of the distance travelled; CREV EXT COND: the cost of conditioning packages to make them re-usable. It comprises the labour costs and depreciation of mechanical devices (if used), for example for unpacking and re-packing products. |

|

CDISP |

Cost of Disposal |

[€/piece] |

Cost of disposing of damaged packages during the manufacturing stage. It comprises the cost of disposal, the cost of transporting damaged packages from the company to the landfill (labour costs, depreciation of vehicles used (e.g. truck), cost of the distance travelled). |

|

RSUB |

Gain from Sub-Product |

[€/piece] |

The parameter identifies the possible gain obtained from the disposal of damaged products. |

|

RUDC |

Gain from Direct Sale of Pallet |

[€/piece] |

This parameter identifies the possible gain obtained from the sale of tertiary packaging to the final customer. |

Table introduces the general formula of the model.

|

Table presents the mathematical model, explaining each cost parameter in detail.

|

The mathematical model allows companies to have a complete tool for analysing the total packaging costs in order to understand packaging cost reductions and consequently the minimization of the impact of total packaging cost on total company cost.

- 9848 reads