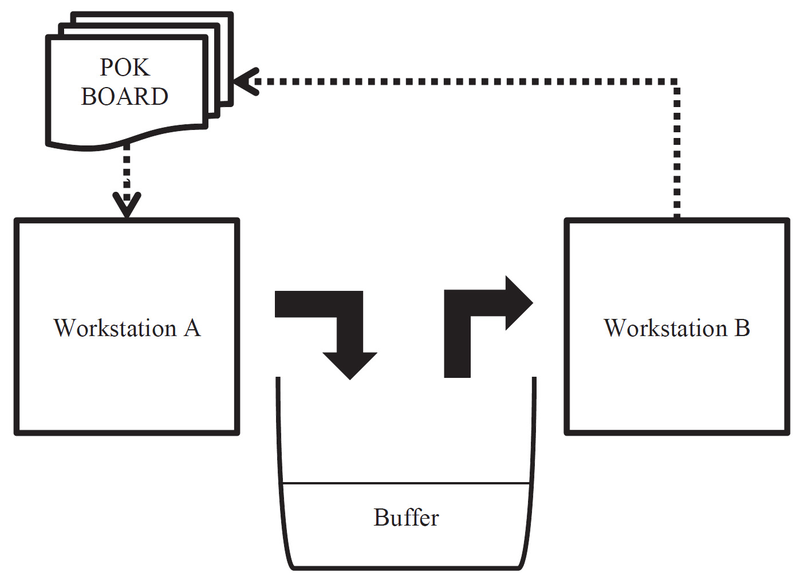

The “one-card” is the simplest implementation of kanban systems. This approach is used when the upstream and downstream workstations (respectively, the preceding and succeeding processes) are physically close to each other, so they can share the same stock buffer. The card is called “Production Order Kanban” (POK)1, 2. The stock buffer acts either as the outbound buffer for the first (A) workstation or as the inbound buffer for the second (B) workstation. A schematic diagram of a one-card system is shown in Figure 6.1.

Here, each container (the JIT unit load) has a POK attached, indicating the quantity of a certain material contained, along with eventual complementary information. The POK also represents a production order for the Workstation A, indicating to replenish the container with the same quantity. When a B operator withdraws a container from the buffer, he removes the POK from the container and posts it on a board. Hence, A operator knows that one container with a specific part-number must be replenished in the stock buffer.

- 12581 reads