The answer to several questions will help determine the proper procedures to use in performing each task.

Can it be eliminated?

If this task or step in the process is eliminated, will the end product or service suffer? Can the purchase of a potato-peeling machine eliminate peeling by hand? If beds are not turned down at night, will guest satisfaction be diminished? Can carpets be cleaned once every nine months instead of twice a year?

The pantry in one restaurant was staffed on the basis of service for three meals a day. When the morning meal was eliminated, staffing remained the same. An analysis of service requirements resulted in fewer employee hours scheduled.

Can it be combined?

Can one employee perform several different jobs? Perhaps general maintenance could be performed by bellhops during slack times of the day. Can employees work with both hands at the same time to improve results?

Are there unnecessary delays?

Are insufficient supplies causing service slowdowns? Holiday Inns found that wheeling a small cart into the guest room saved money when cleaning the room. The materials needed were easily accessible, limiting much walking. In addition, the room attendant felt more comfortable with the door closed. Energy costs were reduced because heat or air-conditioning did not escape from the room as before, when carts were left outside the open door.

Is there misdirected effort?

Can a conveyor belt be used to move food and dishes? Can wheels be put on equipment to roll rather than carry it?

Are skills used properly?

Do we have the right match of employee skill level and task difficulty? Does the employee know the best way to perform the job?

In one hotel, a new regulation requiring that a fire watch be maintained at all public functions caught a supervisor off-guard while a function was taking place. To fill the need, the hotel used a plumber who had not yet gone home. The plumber, working at time and a half, cost much more than was necessary for the job involved.

Are employees doing too many unrelated tasks?

Is the trainee manager being used as a fill-in employee? By asking employees to do too many things, do they end up doing nothing really well?

Is work spread evenly?

At one hotel, 500 room service breakfasts were served between 7.00 and 11.00. In the dining room, service was busiest between 8.30 and 9.00. The entire dish-washing crew was on duty at 7.00, although most of the soiled dishes from room service did not reach the dish-washing station until 10.00. After a study of the situation, it was decided to bring employees in at 9.00. instead of 7.00.

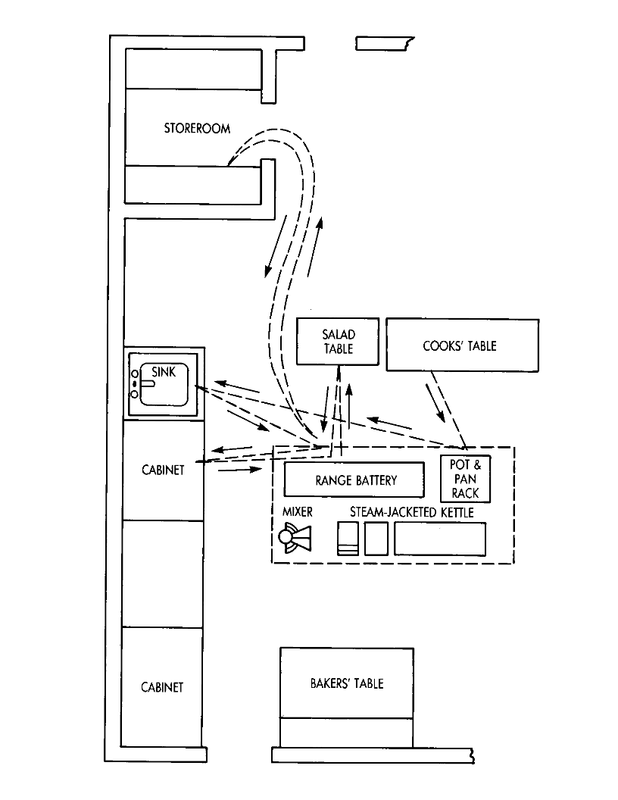

In Exhibit 8, the stages involved in preparing macaroni are laid out. The cook begins at the worktable where the work sheet and recipes are kept. From there the process is:

- ten steps to the pot and pan rack to get the pan;

- thirty steps to the sink to add the water;

- fifteen steps to the range carrying the pan and the water;

- fifty steps to the storeroom while the water is heating, to get the macaroni;

- fifty steps back to the range;

- ten steps to the drawer in the salad table for a spoon;

- ten steps back to the range;

- fifteen steps to the cabinet for salt;

- fifteen steps back to the range;

- fifteen steps to the sink for a little more water;

- fifteen steps back to the range.

This process required the cook to walk a total of 235 steps. In Exhibit 9, a simplified process is suggested for this task. Beginning at the worktable, the cook walks 10 steps to the steam-jacketed kettle, turns on the hot-water faucet located above it, fills the kettle, and turns on the heat; walks 20 steps to the cabinet to get the macaroni and salt; walks back to the kettle; and adds the macaroni and salt, stirring them with a spoon that is stored on a rack over the kettle. The entire process requires that the cook walk only 50 steps.

- 2364 reads