Various time and motion studies have resulted in the development of principles to minimize unproductive body movements. 1

Make rhythmic, smooth motions

An overlapping figure-eight stroke or a circular motion requires less energy than short back-and-forth strokes. This principle can be applied to such tasks as spreading sandwiches, stirring various items, or cutting with a knife.

Make both hands productive

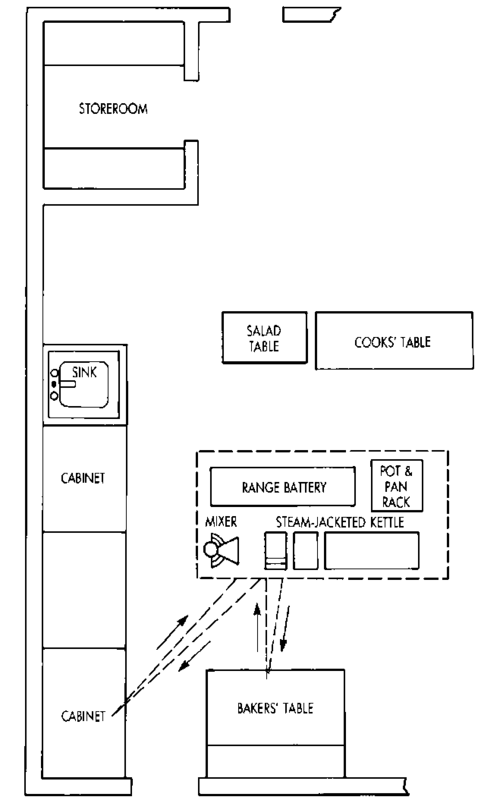

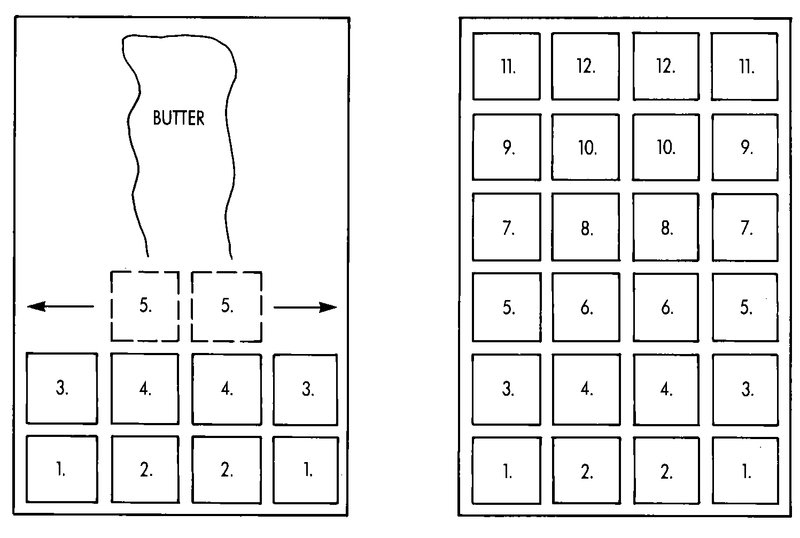

Both hands should be performing similar tasks at exactly the same time. When the hands move symmetrically, there is less body strain. The steps involved in using both hands to make grilled cheese sandwiches are outlined in Exhibit 10. The tray is buttered by ladling melted butter down the center of a pan. Picking up four slices of bread in each hand, the employee simultaneously places the bottom slices in the middle of the tray, then draws them to the sides. This allows the first two slices to be covered with butter while leaving enough butter for the next two slices (each numbered 2 in the figure). The remaining slices are placed in the pan in the order shown, the employee working with both hands at the same time, moving aside already buttered slices to make room for the next slices.

The next step involves placing slices of cheese on the bread. Two slices of cheese are picked up in each hand and both are placed on the number 12 slices of bread. Then, again with each hand, the top slice of cheese is lifted from each number 12 and placed on number 11. This procedure is repeated for slices 10 and 9; 8 and 7; 6 and 5; 4 and 3; and 2 and 1.

A top slice of buttered bread is now placed on the cheese. Melted butter is ladled into another pan. One piece of bread is picked up in each hand, patted in the butter, and placed on the cheese in the first pan. The procedure is repeated until all slices are covered. The pan of sandwiches can then be covered with waxed paper and refrigerated until it is time for toasting.

Keep motions short, simple

Each motion should use the least possible time and energy. If a task can be done with a hand motion, it is a waste of energy to move the entire arm. In the cutting of biscuits, for example, they are worked on a floured breadboard, rolled out with a rolling pin, cut with a biscuit cutter, and transferred to a baking sheet. The leftover dough is then rerolled and re-cut.

It is more efficient, however, to roll the dough directly onto a bun pan. The dough is rolled into a rectangular shape, leaving a one-inch margin (approximately 6.5 centimeters) around the edges of the pan. Biscuits are then shaped into squares or diamonds using a knife or spatula, separating the biscuits as they are cut to ensure even browning. Less time and fewer motions are required. There is no need to re-roll the dough and transfer it to the baking sheet.

Maintain comfortable positions, conditions

The proper height for mixing or beating can be found by standing erect in front of a table with the arms straight and pressing the hands flat on the table. A task such as stirring is very tiring if the forearm is higher than the elbow.

The height of the work surface should let an employee either sit or stand when working. This helps ease monotony as well as physical tiredness.

Similar consideration should be given to providing correct lighting, ventilation, temperature, and humidity while minimizing noise.

Locate materials for efficient motions

There should be a definite and fixed place for all tools and materials, as close as possible to the point of use. Wherever possible, the force of gravity should be utilized to deliver both incoming and outgoing materials. Equipment that is designed for easy grasp will help employees work longer.

Use the best available equipment

Purchasing equipment on wheels will offer dramatic savings in the time and effort to get things done. A simple cart can be used to make one trip from the storeroom with the entire day's supplies rather than requiring many trips during the day.

Yet another example, and one that is overlooked, involves the selection of spoons. The purchase of spoons with insulated handles reduces the chances of being burned by a hot handle during cooking.

Rely on normal work areas

The normal horizontal work area is the space within which work can be done with the least energy. It can be found by making an arc over the work surface by holding the elbow close to the side and swinging the arm out from the elbow. The total normal work area includes the space covered by the combined arcs of both forearms.

The maximum horizontal work area is the space within which an average amount of energy is expended. This area can be found by making arcs over the work surface by extending the full arm outward and swinging it from the shoulder.

The normal vertical work space can be found by making an arc by swinging the lower arm in a circle from the elbow. The maximum vertical work area can be determined by extending the arm and drawing an arc in a relaxed manner. Work is less tiring if the elbow is not raised above shoulder level. The more work that can be done in the normal work areas, the less tiring it will be on the employee.

- 11296 reads