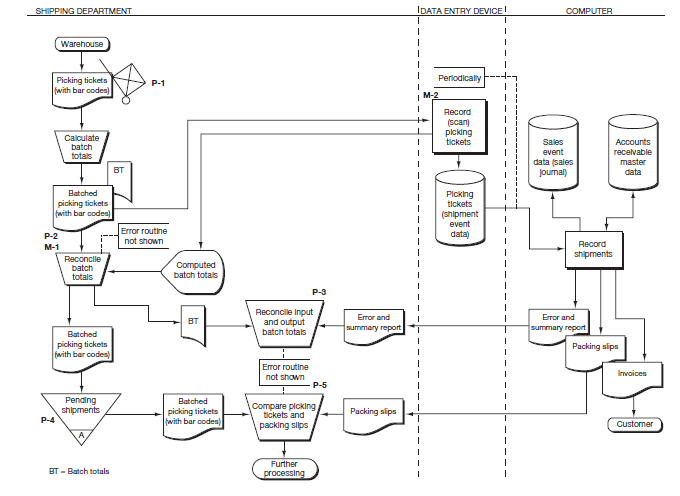

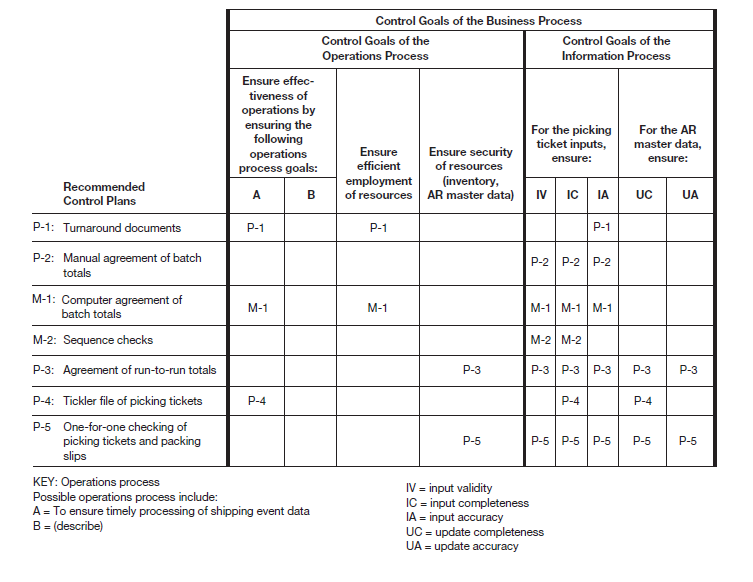

In this section, we apply the control framework to the generic batch processing system described above. Figure 9.8 presents a completed control matrix for the systems flowchart shown in Figure 9.7. Figure 9.7 has been annotated to show the location of recommended control plans that exist in the system (codes P-1, P2, . . . P-5). We also have some control plans that we assume are missing (codes M-1, M-2) because the narrative system description did not mention them specifically. In Figure 9.4 and Figure 9.6, we could not complete certain parts of the top of the control matrix. However, for this example, we have assumed that we know the nature of the input (i.e., picking tickets), we know the resources that are to be protected (i.e., the inventory and the accounts receivable master data), and we know the data that are to be updated (i.e., the AR master data). Therefore, we have completed these elements in Figure 9.8.

This section discusses each of the recommended control plans listed in the first column of the matrix, describing how the plans work.1 Figure 9.4 explains the cell entries appearing in the control matrix. Be sure to trace each plan to the flowchart location where it is implemented (or could be implemented in the case of a missing plan).

Before we start, let’s explain what we mean by batch controls.2 Batch control plansregulate information processing by calculating control totals at various points in a processing run and subsequently comparing these totals. When the various batch totals fail to agree, evidence exists that an event description(s) may have been lost (completeness problem), added (validity problem), or changed (accuracy problem). Once established, batch totals can be reconciled manually or the computer can reconcile them. In general, for batch control plans to be effective, they should ensure that:

- All documents are batched; in other words, the batch totals should be established close to the time that the source documents are created or are received from external entities.

- All batches are submitted for processing; batch transmittals and batch logs are useful in protecting against the loss of entire batches.

- All batches are accepted by the computer; the user should be instrumental in performing this checking.

- All differences disclosed by reconciliations are investigated and corrected on a timely basis.

Batch control procedures must begin by grouping event data and then calculating a control total(s) for the group. For example, Figure 9.7 shows the shipping department employee preparing batch totals for the picking tickets documents to be scanned.

Several different types of batch control totals can be calculated, as discussed in the following paragraphs. You will note in the following discussion that certain types of batch totals are better than others in addressing the information process control goals of input validity, input completeness, and input accuracy.

Document/record counts are simple counts of the number of documents entered (e.g., 25 documents in a batch). This procedure represents the minimum level required to control input completeness. It is not sufficient if more than one event description can appear on a document. Also, because one document could be intentionally replaced with another, this control is not very effective for ensuring input validity and says nothing about input accuracy.

Item or line counts are counts of the number of items or lines of data entered, such as a count of the number of invoices being paid by all of the customer remittances. By reducing the possibility that line items or entire documents could be added to the batch or not be input, this control improves input validity, completeness, and accuracy. Remember, a missing event record is a completeness error and a data set missing from an event record is an accuracy error.

Dollar totals are a summation of the dollar value of items in the batch, such as the total dollar value of all remittance advices in a batch. By reducing the possibility that entire documents could be added to or lost from the batch or that dollar amounts were incorrectly input, this control improves input validity, completeness, and accuracy.

Hash totals are a summation of any numeric data existing for all documents in the batch, such as a total of customer numbers or invoice numbers in the case of remittance advices. Unlike dollar totals, hash totals normally serve no purpose other than control. Hash totals can be a powerful batch control because they can be used to determine if inputs have been altered, added, or deleted. These batch hash totals operate for a batch in a manner similar to the operation of document/record hash totalsfor individual inputs.

|

Review Question Name and explain three different types of batch totals that could be calculated in a batch processing system. |

Now we proceed with an explanation of the controls plans in Figure 9.7 and Figure 9.8.

P-1: Turnaround documents. Turnaround documents are printed by the computer and are used to capture and input a subsequent event. Picking tickets, inventory count sheets, remittance advice stubs attached to customer invoices, and payroll time cards are all examples of turnaround documents. For example, we have seen picking tickets that are printed by computer, are used to pick the goods, and are sent to shipping. The bar code on the picking ticket is scanned to trigger recording of the shipment. When the bar code is scanned the items and quantities that should have been picked are displayed. If the items and quantities are correct, the shipping clerk need only click one key to record the shipment.

P-2: Manual agreement of batch totals. The manual agreement of batch totals control plan operates in the following manner:

- First, one or more of the batch totals are established manually (i.e., in the shipping department in Figure 9.7).

- As individual event descriptions are entered (or scanned), the data entry program accumulates independent batch totals.

- The computer produces reports (or displays) at the end of either the input process or update process, or both. The report (or display) includes the relevant control totals that must be manually reconciled to the totals established prior to the particular process.

- The person who reconciles the batch total (see the shipping department employee in Figure 9.7) must determine why the totals do not agree and make corrections as necessary to ensure the integrity of the input data.

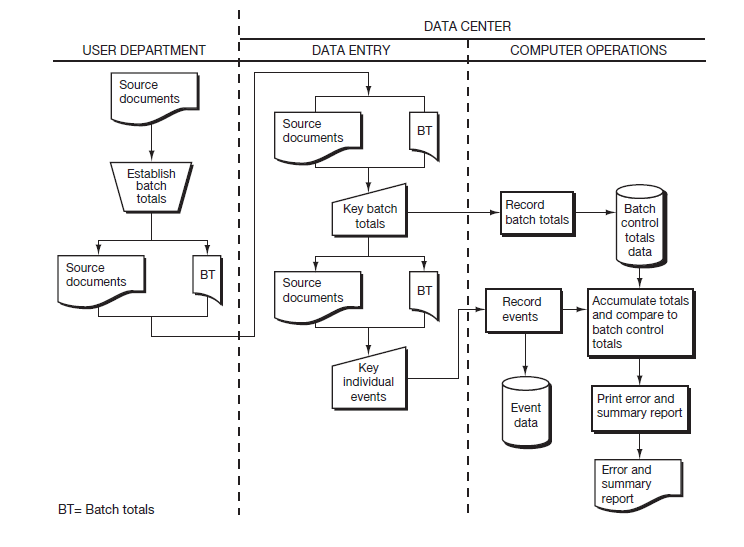

M-1: Computer agreement of batch totals. This control plan does not exist in Figure 9.7 and therefore is shown as a missing plan. Note in Figure 9.7 where we have placed the M-1 annotation. The computer agreement of batch totals plan is pictured in Figure 9.9 and works in the following manner:

- First, one or more of the batch totals are established manually (i.e., in the user department in Figure 9.9).

- Then, the manually prepared total is entered into the computer and is recorded on the computer as batch control totals data.

- As individual event descriptions are entered, a computer program accumulates independent batch totals and compares these totals to the ones prepared manually and entered at the start of the processing.

- The computer then prepares a report, which usually contains details of each batch, together with an indication of whether the totals agreed or disagreed. Batches that do not balance are normally rejected, and discrepancies are manually investigated. Such an analysis would be included in a report similar to the “Error and summary report” in Figure 9.7 and Figure 9.9.

M-2: Sequence checks. Whenever documents are numbered sequentially—either assigned a number when the document is prepared or prepared using prenumbered documents—a sequence check can be applied to those documents. One of two kinds of sequence checks may be used—either a batch sequence check or a cumulative sequence check.

In a batch sequence check, the event data within a batch are checked as follows:

- The range of serial numbers constituting the batch is entered.

- Each individual, serially prenumbered event is entered.

- The computer program sorts the event data into numerical order, checks the documents against the sequence number range, and reports missing, duplicate, and out-of-range event data.

Batch sequence checks work best when we can control the input process and the serial numbers of the input data. For example, this control would not work for entering customer orders that had a variety of numbers assigned by many customers.

A slight variation on the batch sequence check is the cumulative sequence check. The cumulative sequence check provides input control in those situations in which the serial numbers are assigned within the organization (e.g., sales order numbers issued by the sales order department) but later are not entered in perfect serial number sequence (i.e., picking tickets might contain broken sets of numbers). In this case, the matching of individual event data (picking ticket) numbers is made to a file that contains all document numbers (all sales order numbers). Periodically, reports of missing numbers are produced for manual follow-up.

Reconciling a checkbook is an example of a situation in which numbers (the check numbers) are issued in sequence. But when we receive a bank statement, the batch may not contain a complete sequence of checks. Our check register assists us in performing a cumulative sequence check to make sure that all checks are eventually accounted for.

P-3: Agreement of run-to-run totals. This is a variation of the agreement of batch totals controls. With this control, totals prepared before a computer process are compared, manually or by the computer, to totals prepared after the computer process. The controls after a process are often found on an error and summary report. When totals agree, we have evidence that the input and the update took place correctly. This control is especially useful when there are several intermediate steps between the beginning and the end of the process and we want to be assured of the integrity of each process.

P-4: Tickler files. A tickler file is a file that is reviewed on a regular basis for the purpose of taking action to clear items from that file. In Figure 9.7, we see a file of picking tickets representing items that should be shipped. Should these documents remain in this file for an extended period of time, we would fail to make the shipments or to make them in a timely manner. Tickler files may also be computer records representing events that need to be completed, such as open sales orders, open purchase orders, and so forth.

P-5: One-for-one checking. One-for-one checking is the detailed comparison of individual elements of two or more data sources to determine that they agree as appropriate. This control is often used to compare a source document to an output produced later in a process. Differences may indicate errors in input or update. If the output cannot be found for comparison, there is evidence of failure to input or process the event. While this procedure provides us details as to what is incorrect within a batch, agreement of run-to-run totals will tell us if there is any error within a batch. One-for-one checking is expensive and should be reserved for low-volume, high-value events.

|

Review Question How does each control plan listed in the control matrix in Figure 9.8 work? |

Having examined what each of the recommended control plans means and how each operates, we can now look at how the plans meet the control goals. Table 9.4 explains the relationship between each control plan and each control goal that it helps to achieve. As you study Table 9.4, we again urge you to concentrate your energies on understanding these relationships.

|

P-1: Turnaround documents. Operations process goal A, Efficient employment of resources: By reducing the amount of data that must be input to record the shipment, we improve the speed and productivity of the data entry personnel. Input accuracy: Using a pre-recorded bar code to trigger the event reduces the possibility of input errors. P-2: Manual agreement of batch totals. Input validity, Input completeness, Input accuracy: Agreement of the batch totals at this point ensures that only valid source documents comprising the original batch have been input (input validity), that all source documents were input (input completeness), and that data elements appearing on the source documents have been input correctly (input accuracy). M-1: Computer agreement of batch totals. Operations process goal A, Efficient employment of resources: Had the computer been used to reconcile the control totals, the processing of the events would have been completed more quickly and with less human effort. Input validity, Input completeness, Input accuracy: Regarding these control goals, the effect of this control is the same as P-2. Agreement of the batch totals at this point would have ensured that only valid source documents comprising the original batch had been input, that all source documents were input, and that data elements appearing on the source documents had been input correctly. M-2: Sequence checks. Input validity, Input completeness: By comparing an expected sequence of documents to those actually input, the sequence checks can detect a second occurrence of a particular document number, which would suggest that the second event is invalid, and can detect missing document numbers, suggesting that not all events had been input. P-3: Agreement of run-to-run totals. Security of resources, Input validity: By determining that updates to the accounts receivable master data reflect goods picked and about to be shipped, we reduce the possibility of recording an invalid sales event and shipping to customers who did not order, and will not pay for the goods. Input completeness, Input accuracy, Update completeness, Update accuracy: By comparing totals prepared before the input to those produced after the update, we ensure that all events were input (input completeness), all events were input correctly (input accuracy), all events were updated to the master data (update completeness), and all events were updated correctly to the master data (update accuracy). P-4: Tickler file of picking tickets. Operations process goal A, Input completeness, Update completeness: A file of picking slips is retained in shipping awaiting the packing slips. If the packing slips are received in a timely manner, and the corresponding picking ticket removed from the “Pending shipments” file, we can ensure that goods will be shipped in a timely manner and that the picking tickets were indeed input and updated the master data. P-5: One-for-one checking of picking tickets and packing slips. Security of resources, Input validity: By matching details on the picking tickets with the data on the packing slips produced by the computer, we reduce the possibility that an invalid sales event has been recorded and that we will not ship goods to customers who did not order, and will not pay for the goods. Input completeness, Input accuracy, Update completeness, Update accuracy: By matching details on the picking tickets (i.e., the inputs) with the details on the packing slips produced by the computer, we ensure that all events were input (input completeness), all events were input correctly (inputaccuracy), all events were updated to the master data (update completeness), and all events were updated correctly to the master data (update accuracy). |

- 9434 reads