The basic decision that management must make when contemplating global sourcing is the so-called buy vs. make decision. Should the firm buy the product from another company, or should it make the product itself, in an offshore plant acquired or built by the company?

For global corporations the buy vs. make decision is not a simple either/or proposition. In general, an MNC has a far greater range of alternatives to choose from than does a domestic company or a small international company.

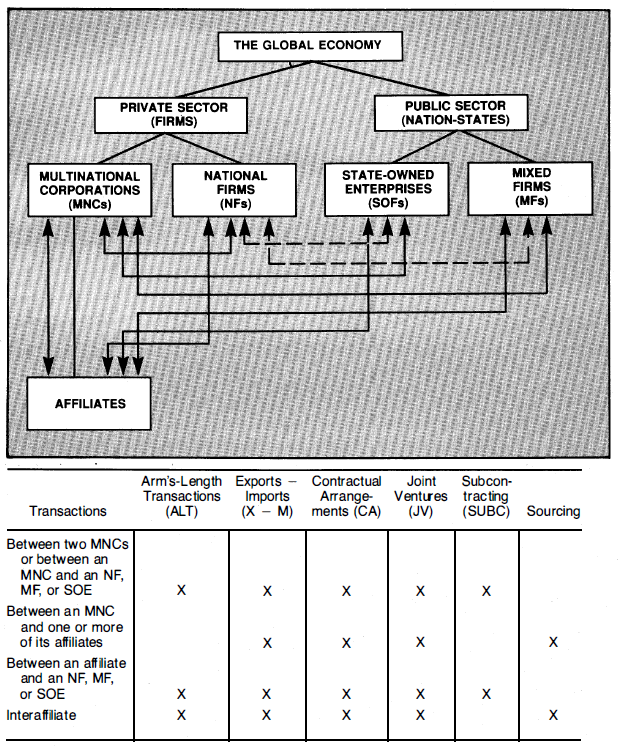

Figure 13.3 provides a simplified picture of the numerous connections among the main actors in the global business game. As has been pointed out, the systems approach dictates that the study of the functions of a global company focus on the relationships between the firm and its external environment. Thus the two main systems depicted in Figure 13.3-the private sector (firms) and the public sector (nation-states)--each include subsystems. The private sector's subsystems are the MNCs and national firms (NFs). The public sector consists of state-owned enterprises (SOEs) and mixed firms (MFs), which have a mixture of public-sector and private-sector equity. Business transactions among NFs, MFs, and SOEs fall into the category of national transactions or within-border transactions and therefore are not dealt with here. Business transactions between MNCs and the three other types of enterprises are international transactions and are the subject of this chapter. As Figure 13.3shows, an MNC interacts with the other three actors both directly and via its affiliates (shown at the bottom of the figure).

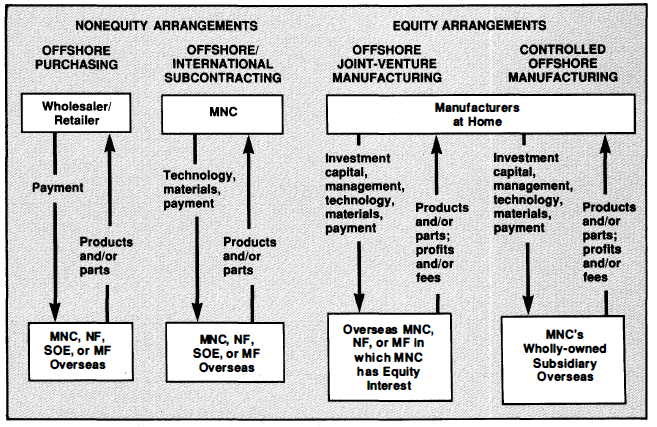

The basic decision of a production management team as to whether to buy or make determines the basic nature of the global sourcing arrangement equity or nonequity.

- (1) Nonequity arrangements include

- Offshore purchasing

- Offshore international subcontracting

- (2) Equity arrangements include

- Offshore joint-venture manufacturing

- Controlled offshore manufacturing

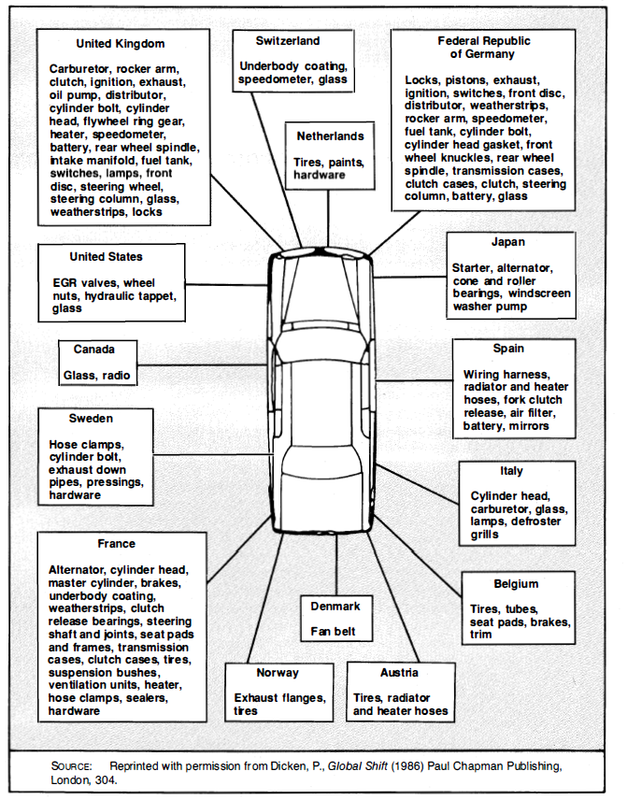

Figure 13.4depicts the most widely used forms of international sourcing. The version of global sourcing most often reported by the professional business periodicals is offshore purchasing. Buying parts somewhere abroad is very popular with big manufacturing companies such as Ford and General Motors. Japanese Sogoshoshas introduced American buying groups to this practice, which has been largely responsible for elevating the countries of Singapore, Taiwan, Hong Kong, and South Korea to the status of countries (NICs). Since this type of international business transaction is an arm's-length transaction, it will not be further treated here. Figure 13.5 shows where Ford purchases the various parts for the European Escort.

The two types of global sourcing currently at the forefront of academic, government, and management attention are offshore subcontracting and controlled offshore manufacturing. Offshore, or international, subcontracting is viewed by most government officials as the best way to develop indigenous industry without substantial long-term borrowing from abroad. Controlled offshore manufacturing is considered by MNC management as the best means of smoothing or rationalizing global production and by governments as the best way of keeping labor from migrating to other countries. The intermediate strategy of offshore joint-venture manufacturing offers some of the advantages of each of the other strategies.

The United Nations and most national governments pay considerable attention to international subcontracting because of its importance to national firms in developing countries and to small businesses in developed countries. The United Nations distinguishes between two main types of international subcontracting: industrial and commercial. This distinction is based on the general classification of goods into industrial products (such as parts and components), which are used for further processing, and commercial products, which are ready for final consumption.

The United Nations' Industrial Development Organization (UNIDO) definition of subcontracting applies essentially to industrial subcontracting.

A subcontracting relationship exists when a firm (the principal) places an order with another firm (the subcontractor) for the manufacture of parts, components, subassemblies or assemblies to be incorporated into a product which the principal will sell. Such orders may include the treatment, processing or finishing of materials or parts by the subcontractor at the principal's request. 1

Subcontracting is a kind of halfway point between engaging in arm's-length transactions on the open market and setting up brick and mortar facilities in each market. It offers the obvious advantage of a low fixed investment. In addition, perhaps its greatest advantage is the degree of flexibility or maneuverability it offers. Usually, but not always, there is a dependent relationship between the initiating company and the subcontractor. Particularly where one large firm subcontracts to several small firms, the small subcontractors may perform the "shock-absorbing," or buffering, function described at the beginning of the chapter. By using small subcontractors instead of warehousing raw material and final products, a large firm can externalize some of the risks involved in buying large quantities of raw materials and components and carrying large inventories of finished products. As small business advocates and United Nations officials point out, from the MNC's point of view small subcontractors are "expandable and expendable.” 2

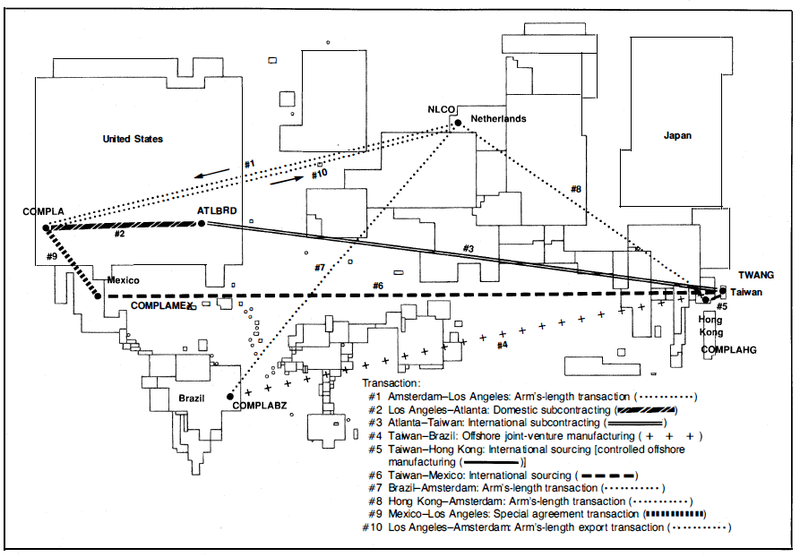

Figure 13.6 presents a picture of a hypothetical company's global sourcing relationships. A U.S. computer manufacturer in Los Angeles, COMPLA, INC., receives the next quarter's sales forecast from its sales office, NLCO, in Amsterdam, calling for 150,000 computers. This transaction, labeled # 1, is an international transaction of the arm's-length type. COMPLA subcontracts to the Atlanta-based company ATLBRD, Inc. the supplying of 150,000 main boards (transaction #2, domestic subcontracting). ATLBRD subcontracts to a Taiwanese board manufacturer, TWANG Ltd., the production of 150,000 boards (transaction #3, international subcontracting).

The 150,000 boards are distributed from Taiwan as follows: 50,000 boards are shipped to COMPLA's joint-venture subsidiary in Brazil, COMPLABZ, S.A., for assembly (transaction #4, offshore joint-venture manufacturing equity arrangements); 50,000 are shipped to COMPLA's wholly owned subsidiary in Hong Kong, COMPLAHG, Ltd., to be assembled into final products (transaction #5, international sourcing); the remaining 50,000 boards are shipped to COMPLA's across-the-border maquiladora in Mexico, COMPLAMEX, S.A. (transaction #6, international sourcing).

The finished computers are supplied to the Amsterdam COMPLA's sales office as follows: Brazil ships 50,000 computers directly to Amsterdam (transaction #7, arm's-length export transaction); Hong Kong ships 50,000 computers to Amsterdam (transaction #8, arm's-length export transaction); the remaining 50,000 computers produced by COMPLAMEX are reexported from Mexico into the United States (transaction #9, maquiladora 406-407 U.S.-Mexico, a special agreement transaction) and exported to the Netherlands (transaction #10, arm's-length export transaction).

- 2317 reads